DPU80r Reversible Vibratory Plates

Sturdy and compact in design, the DPU80r offers the same superb compaction performance as its sister model with center pole. Even when it comes to control, it is in no way inferior: On turns, the vibratory plate can be variably steered — and very precisely. The innovative steering imbalances provide for superior rotational dynamicsand extremely easy control without loss of propulsion Due to the intelligent remote control technology between the vibratory plate and the operator, the latter is well protected against vibrations, emissions and noise. The DPU80r is a model from our 80 to 130 kN range of powerful heavy vibratory plates.

- Powerful vibratory plate designed optimally for heavy soils

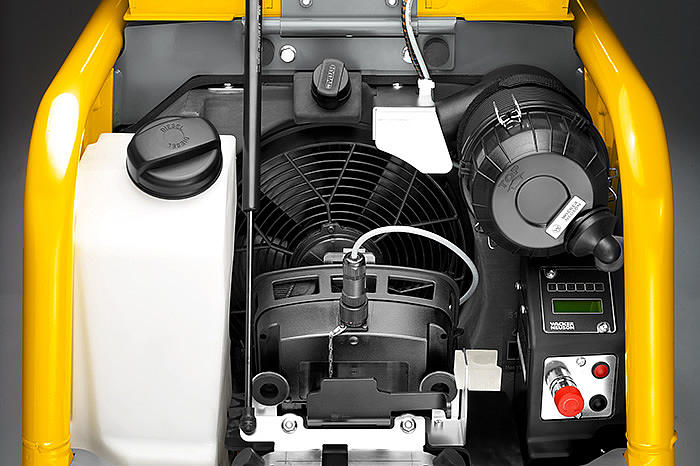

- Intelligent water-cooled engine for ambient temperatures up to 50°C

- Available as a remote-controlled or alternatively center pole controlled version

- Compamatic: additional compaction control, conveniently from your desk (accessories for machines with compatec)

Optimal compaction control with Compamatic

- Compamatic is a function in the EquipCare Manager connecting compaction control and Telematics

- The new function helps you to better plan construction site procedures and to ensure quality

- Due to this, a machine’s success with compaction is traceable from your desk in the EquipCare Manager

- Simply affix the Compamatic module (accessories for machines with compatec) to the machine. The module transmits the machine’s location and compaction data via GPRS to the EquipCare Manager.

First-class compaction performance

- Individually controllable compaction performance, ideally adjustable to the soil to be compacted

- Water-cooled engine, optimally matched to the vibratory plate

- Sturdy base plate: very good travel rate for fast compaction with optimal results

Optimal dimensions

- Tailored to individual requirements: available in two operating widths, 670 or 770 mm

- Only 830 mm high: low design thanks to the transversely installed engine — optimal for application in confined spaces, for example in trench shoring

Remote Control for great user comfort

- Precise and continuously variable control in curves

- The remote control can be recharged under the plate’s lockable hood. This also provides protection against theft.

- The simultaneous operation of several remote controlled vibratory plates is easily possible

- Intuitive controls, no training necessary

- Very safe: The remote control only works when in direct visual contact with the plate

- Optimum protection: The infrared sensor gives way when pushed down

- The proximity recognition protects the operator from losing control

Ecological and sustainable

- The water-cooled engine complies with all emission regulations sustainably and allows operation at extreme temperatures

- Water-cooling provides extremely long engine service life even with long-term operations

- Way below noise exposure limits — protecting the environment and the operator