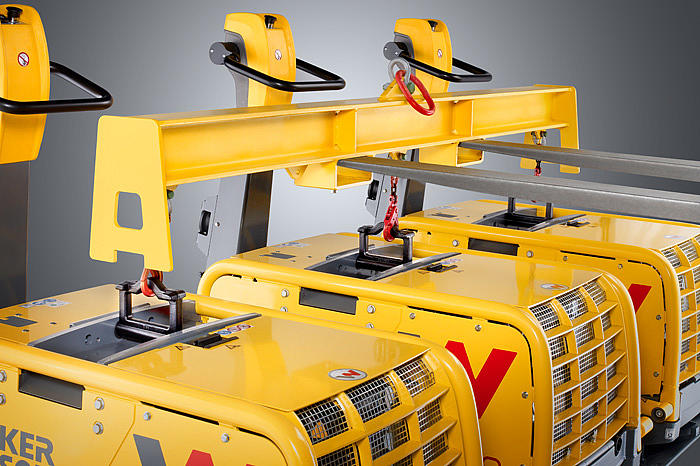

Coupling Set Reversible Vibratory Plates

The coupling set is the ideal machine for compacting gravel in track construction. It is light enough not to sink in the track bed and has a large working width of three meters. It prepares a large area within a very short time. The entire track bed can be compacted with a few steps of operation. The three coupled DPU110 vibratory plates can also be decoupled and used individually. Thus they offer maximum flexibility and are easier to transport. The operation of the coupling set is very safe thanks to the infrared remote control. As soon as the operator comes too close to the machine, it automatically switches off due to the integrated near field detection. It also protects the operator from dust, emissions and noise.

- Extreme working width of 3 m, with only one pass a very wide area can be compacted - more than 4,300 square meters per hour.

- Stable mechanical coupling of the machines, easy to install in a few simple steps.

- "Plug and Play", automatic setup of the infrared connection between the machines

- Even when compacting soil, the coupling set very efficiently compacts large areas in a short time.

- Compaction control from the desk: The new function Compamatic offers visualization and documentation of compaction in real time via GPRS in the EquipCare Manager.

Infrared remote control

- More comfort and safety for the operator. He stands apart from the risk of injury, noise and dust and is not exposed to hand-arm vibrations.

- The near field detection and the line of sight feature prevents the machine from getting too close to the operator or out of control.

- If the connection is interrupted for a short time, no intervention of the operator is necessary, thus faster continued processing.

- The remote control is rechargeable under the lockable hood, no cable operation is necessary.

- Safe operation on slopes thanks to remote control, no risk of falling for the operator.

-

A light signal provides constantly information about the connection status of the coupling set and the remote control: Yellow flashing (fast) = connection search

Yellow lights = connection found

Yellow flashing (slow) = ready

Red light = connection interrupted

Compamatic: Compaction control from the desk

- Which area has been compacted already and how high is the degree of compaction – this is now displayed by Compamatic, additionally to the other proven telematics functions.

- It detects the machine location via GPS and documents the compaction progress on a map which can be called up in the EquipCare manager.

- This documentation and visualization of compaction provides a quick overview of work progress and compaction quality.

Maintenance and Service

- 100% service access with a few easy steps

- Detachable side panels

- Hood can be fully opened

- Long service intervals due to large air filter

- Easy to clean base design without the risk of damaging hydraulic hoses

Ecological and sustainable

- The water-cooled engine meets all emission regulations future-proof and allows operation at extrem temperatures

- Water-cooling provides extremely long engine service life even with long-term operations

- Way below the noise exposure limits - that protects the environment and operator

Extremely robust design

- The steel tube frame and steel cover sheets make the DPU110 very robust and protected against damage

- The side panels are detachable

- Durable and very stable design